TRAFOGUARD®

Individual monitoring system for network transformers

Your benefits at a glance

|

Product description

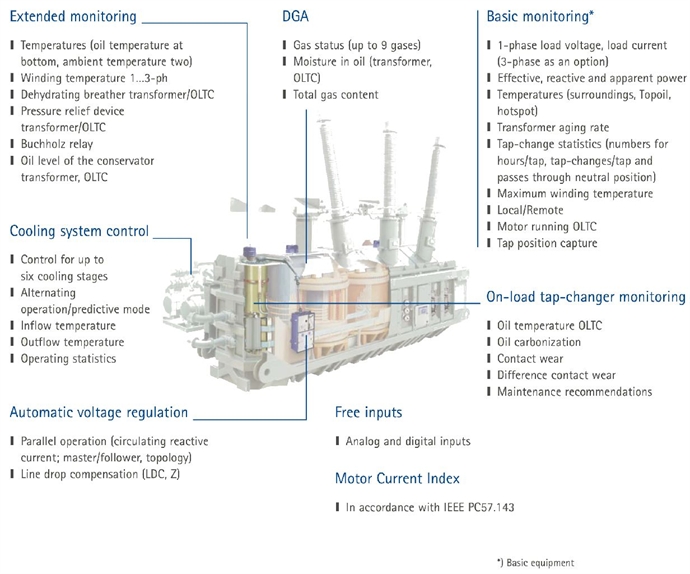

Collecting, processing, displaying and forwarding operating data from transformers – the TRAFOGUARD® provides you with all of these functions in one device. Regardless of whether simply displaying the status or generating individual reports, the TRAFOGUARD® features an outstanding variety of function offerings and a particularly high operating comfort level. And all that in the form of a 19" device.

The TRAFOGUARD® makes an impression with its maximum flexibility and individuality in bringing functions together. The system enables customer-specific expansion of the basic functions by individually selectable and combinable supplementary modules. Different function packs can be taken into account when ordering or even after. Not only standard functions, such as voltage and temperature measurement, but also wide-ranging functions such as DGA and step switching monitoring are among the function packs.

Quick and user-friendly parameterization and configuration of the TRAFOGUARD® is guaranteed by the proprietary MR software TRAFOSET.

The visualization and preparation of the measured values also provides a high degree of flexibility. All measured values, events and binary states can be transferred to a local PC or, via remote access, to the control center. The representation via MR's new TRAFOVISOR MR visualization interface can be adapted to the respective user requirements conveniently and displayed in the form of graphics or tables.

The TRAFOGUARD® makes operating states transparent, enables analysis of current and historical operating data, and supports the technician in recognizing critical situations at an early stage.

Now, the TRAFOGUARD® offers even more. The facelift has added even more useful functions. For example, DNP3 was implemented as the remote communication protocol, 3-phase measurement was integrated as well as OLTC monitoring via motor current index in accordance with IEEE PC57.143 for MR tap changers and other brands. Modifying parameters and the configuration remotely is fast and easy using the TRAFOSET® and TAPCON-trol software packages. Integration into redundant network systems is now also possible using the RSTP and PRP protocols.

Technical Data

|

TRAFOGUARD |

||

| On-load tap changer monitoring |

|

|

|

Calculating all important maintenance criteria |

|

|

|

Signaling the next pending maintenance |

|

|

|

Taking the soot content into account (only OILTAP®) |

|

|

|

Calculating the contact wear (only OILTAP®) |

|

|

|

Showing the lifetime of the vacuum interrupters of existing MR on-load tap-changers (only VACUTAP®) |

|

|

|

Monitoring the on-load tap-changer |

|

|

|

Monitoring the motor linkage and the smooth running in the three-column version |

|

|

|

Controlling the motor-drive unit heater |

|

|

|

Motor Current Index |

||

| Communication |

|

|

|

IEC60870-5-101/103 |

|

|

|

DNP3 |

|

|

|

MODBUS ASCII/RTU |

|

|

|

Siemens LSA |

|

|

|

IEC61850 |

|

|

| Tap position capture |

|

|

|

BCD |

|

|

|

Current signal |

|

|

|

Voltage signal |

|

|

|

Resistor contact series |

|

|

|

Resolver |

|

|

|

Cooling system control |

|

|

| Basic monitoring of the transformer |

|

|

|

Load current, load voltage |

|

|

|

Ambient temperature |

|

|

|

Tap position (analog, BCD) |

|

|

|

Effective and apparent power |

|

|

|

Aging rate |

|

|

|

Tap-change operation statistics |

|

|

|

Top oil temperature |

|

|

|

Winding temperature |

|

|

|

Hot spot |

|

|

| Extended monitoring of the transformer |

|

|

|

Bottom oil temperature |

|

|

|

Winding temperature 1, 2, and 3 |

|

|

|

Second ambient temperature |

|

|

|

Oil level of the conservator transformer, OLTC |

|

|

|

Dehydrating breather transformer |

|

|

| DGA (Dissolved gas analysis) |

|

|

|

Acquiring DGA sensor information (up to 9 gasses) |

|

|

|

Moisture in oil (transformer, OLTC) |

|

|

|

Total gas content |

|

|

| Cooling system monitoring |

|

|

|

Inflow temperature |

|

|

|

Outflow temperature |

|

|

|

Operating statistics |

|

|

|

Efficiency |

|

|

|

Monitoring the cooling system |

|

|

| Voltage regulation |

|

|

|

Voltage regulation, including line drop compensation |

|

|

|

Parallel mode |

|

|

|

Customer-specific topology |

|

|