TAPMOTION® TD ISM®

INNOVATIVE MOTOR-DRIVE SOLUTIONS

WITH INTEGRATED MONITORING.

Benefits for you at a glance:

|

Product description

Key improvements – maximum customer benefit

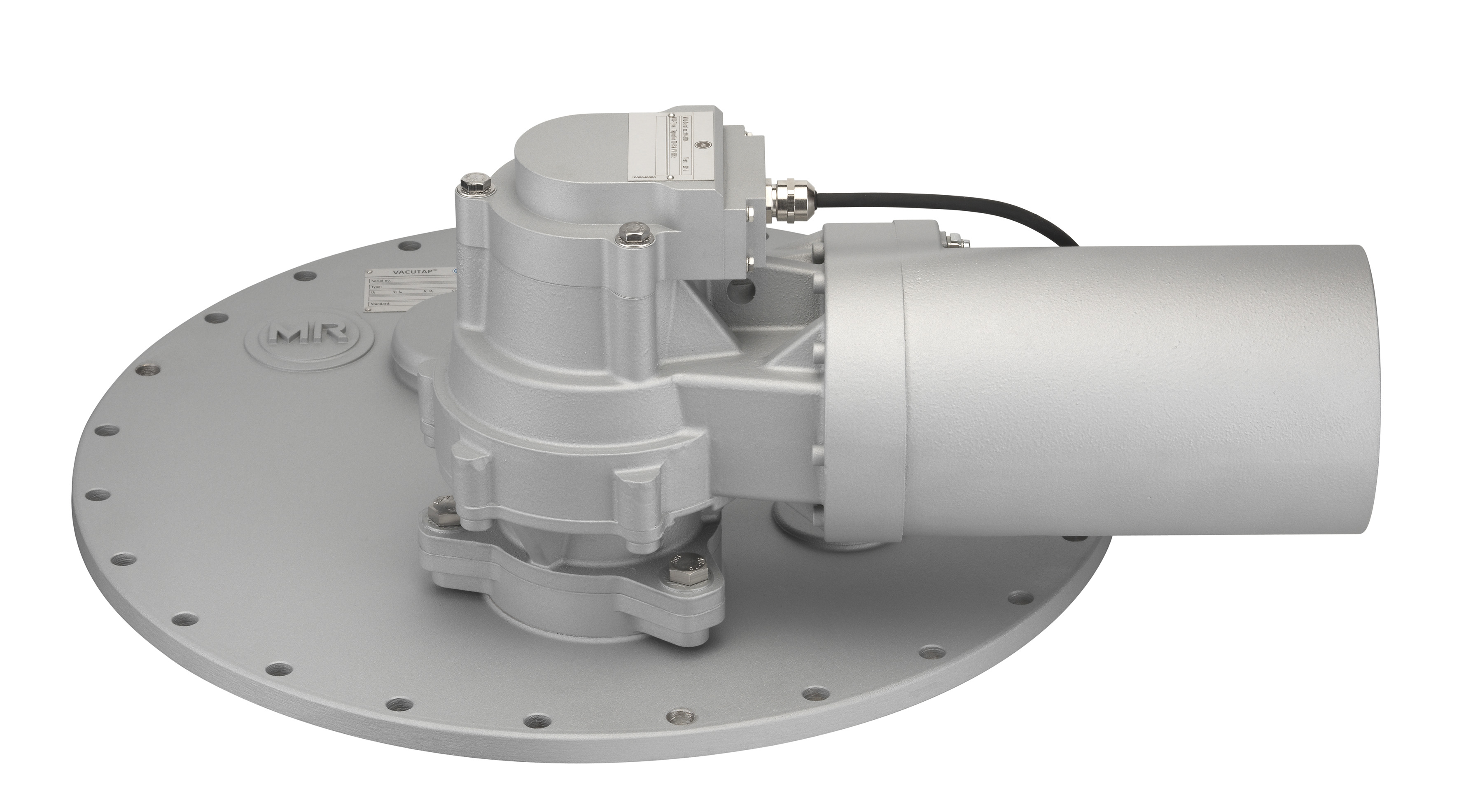

In the TAPMOTION® TD ISM®, the drive energy is made available precisely where it is needed, at the tap changer cover. The drive commands generated in the control cabinet are transmitted to the motor installed above via a cable connection. This removes the need for a rigid drive shaft connection and the complex and time-intensive task of installing it. What's more, the precise motor torque delivered to the driven tap changer guarantees maximum safety when switching loads.

In the TAPMOTION® TD ISM®, the drive energy is made available precisely where it is needed, at the tap changer cover. The drive commands generated in the control cabinet are transmitted to the motor installed above via a cable connection. This removes the need for a rigid drive shaft connection and the complex and time-intensive task of installing it. What's more, the precise motor torque delivered to the driven tap changer guarantees maximum safety when switching loads.

TAPMOTION® TD ISM® – the integrated motor-drive solution

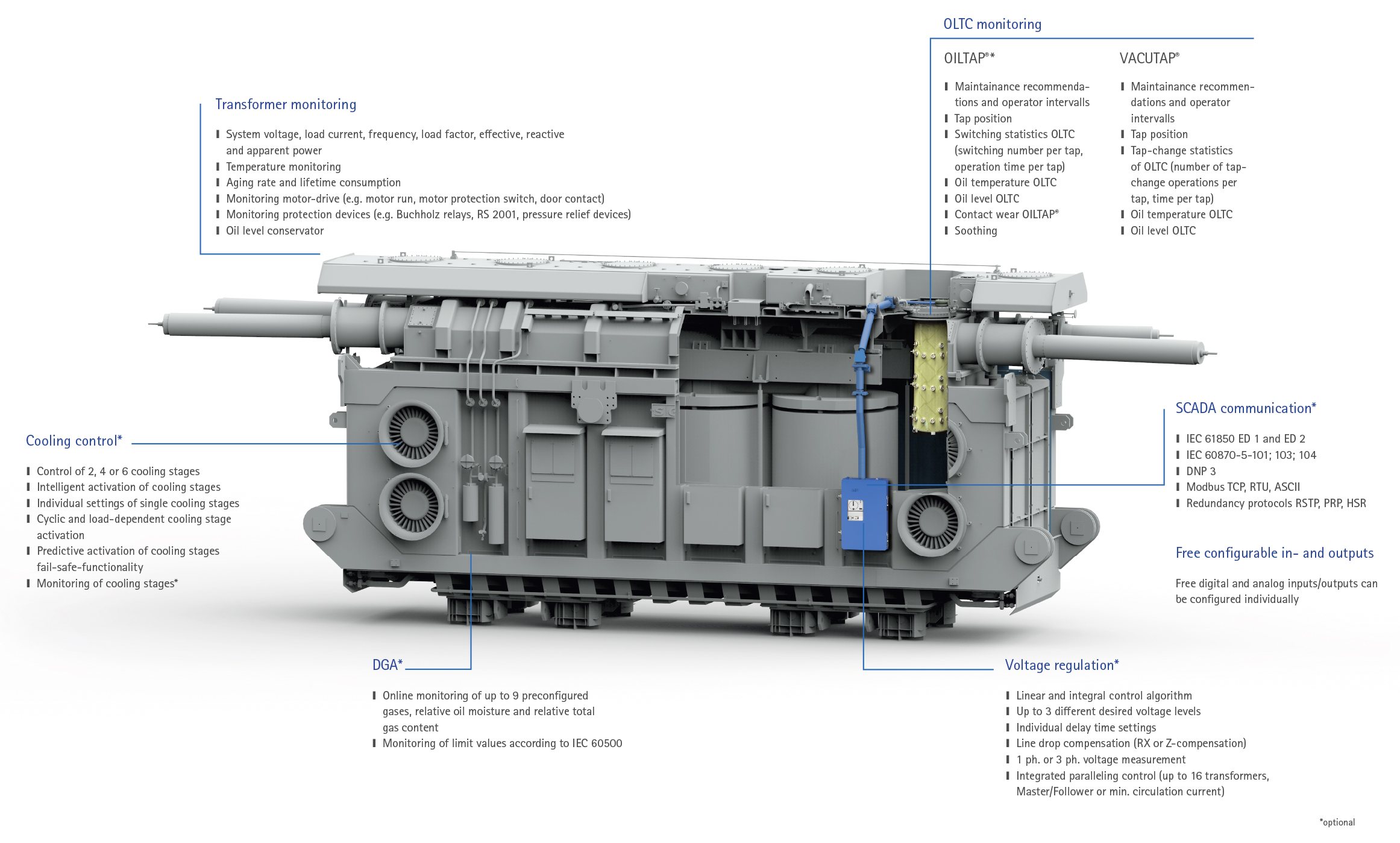

The TAPMOTION® TD ISM® is factory-fitted with our very own ISM® (Integrated Smart Module) technology. This electronic automation platform is particularly well suited to the special conditions of energy technology. As well as Controlling the drive of the on-load tap-changer, this state-of-the-art automation platform also enables the recording and Evaluation of all relevant operating data from the power transformer. This allows you to plan how you operate, service, andreplace your equipment in a more efficient and targeted manner. Providing you with intelligent operational Management and optimized asset management.

The TAPMOTION® TD ISM® is factory-fitted with our very own ISM® (Integrated Smart Module) technology. This electronic automation platform is particularly well suited to the special conditions of energy technology. As well as Controlling the drive of the on-load tap-changer, this state-of-the-art automation platform also enables the recording and Evaluation of all relevant operating data from the power transformer. This allows you to plan how you operate, service, andreplace your equipment in a more efficient and targeted manner. Providing you with intelligent operational Management and optimized asset management.

The simple connection and configuration process for the transformer sensors means that commissioning can be carried out quickly. In addition to the monitoring functions, you can also take Advantage of the freely available inputs which will allow you to configure your monitoring process exactly how you want it in the future.

The recorded and evaluated data can be transferred directly to SCADA. This greatly reduces the amount of wiring needed during installation and significantly cuts costs compared with a conventional connection method. Visualization takes place via an integrated web server with ISM® IICI (Intuitive Control Interface). There is no need to install any other software.

Technical Data

For visualization following internet browsers are recommended, as of the version mentioned:

• Internet Explorer 10

• Mozilla Firefox (Version 29)

• Google Chrome (Version 35)